Vortex Tube Compressed Air Cooling

A vortex tube is a tool that can take normal compressed air and convert it into two air streams; one stream is hot air and the other stream is cold air. The cold air side can be used to cool a variety of machining applications and processes. Vortex tube have no moving parts, which translates into no maintenance. The cold air can be adjusted down to -50 degrees Fahrenheit, and the hot side can be adjusted up to a temperature of 260 degrees Fahrenheit.

USES FOR VORTEX TUBES

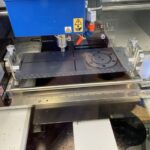

• COOLING OF MACHINE OPERATION

• COOLING ELECTRICAL CABINETS

• COOLING MOLD TOOLS

• COOLING SEWING NEEDLES

• COOLING OF HOT OPERATIONS

• COOLING WORKERS

• TESTING THERMOSTATS

• COOLING CCTV CAMERAS

• SETTING HOT GLUE OPERATIONS

• COOL SOLDERING

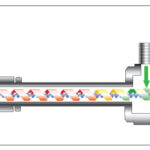

• HOW DO VORTEX TUBES WORK?

• INDUSTRIAL SPOT COOLING

Compressed air is injected into the vortex tube cooler at extremely high speeds and that creates a cyclone, or vortex, spinning a million revolutions per minute. Part of the air is forced to spin inward to the center and travels up a long tube where a valve turns the spinning column of air inside itself. The inside column of air gives up its heat to the outside column. The cold air is directed out the cold end of the Vortex Tube and the hot air is directed out the other end of the Vortex Tube.

The air flow and temperature are totally controllable. And since there are no moving parts there is little need for maintenance. A Vortex Tube is useful in many applications from spot cooling to creating a "cooling chamber" in a haunted house. If you have any questions about using a vortex tube please call to discuss your application.

FEATURES

• RELIABLE—NO MOVING PARTS

• MAINTENANCE FREE

• STAINLESS STEEL CONSTRUCTION

BENEFITS

• SPOT COOL

• THERMAL CYCLE PARTS

• COOL GAS SAMPLES

• COOL PARTS

• COOL HEAT SEALING